Free Welder Performance Qualification Record PDF Form

Misconceptions

Misconceptions about the Welder Performance Qualification Record (WPQR) form can lead to confusion in the welding industry. Here are nine common misconceptions along with explanations to clarify them.

- It is only necessary for certified welders. Many believe that only certified welders need a WPQR. In reality, anyone who performs welding tasks may benefit from having a record, regardless of certification status.

- The WPQR is the same as a welding certification. Some people think these terms are interchangeable. However, the WPQR is a record of performance, while a welding certification is an official acknowledgment of a welder's skills.

- All welding processes require a separate WPQR. Many assume that each welding process needs its own WPQR. In fact, one WPQR can cover multiple processes if the welder is qualified for them.

- Only the welder's name is important on the WPQR. Some focus solely on the welder's name, overlooking other critical details. Information like the test number, specifications used, and mechanical test results are equally important for validation.

- Once qualified, a welder never needs to update their WPQR. This misconception suggests that a WPQR is a one-time document. In truth, welders must update their WPQR whenever they change processes, materials, or techniques.

- The WPQR is not relevant for non-destructive testing. Some believe that non-destructive testing results do not need to be included. However, these results are essential for verifying the quality of the welds performed.

- Only the results matter, not the process. It is a common belief that only the outcome of the welding process is significant. Yet, the methods and variables used during welding are crucial for understanding the results.

- Visual inspection is optional on the WPQR. Many think visual inspection can be skipped. However, visual inspection is a mandatory part of the qualification process and must be documented.

- The WPQR is not needed for temporary projects. Some individuals believe that temporary projects do not require a WPQR. This is incorrect; maintaining a WPQR helps ensure quality and safety, regardless of project duration.

Understanding these misconceptions can help ensure that welders and employers maintain proper documentation and uphold industry standards.

Documents used along the form

The Welder Performance Qualification Record (WPQR) is an essential document for verifying a welder's skills and capabilities. It often works in tandem with several other forms and documents that help ensure compliance with industry standards and safety regulations. Here’s a list of related documents that are commonly used alongside the WPQR.

- Welding Procedure Specification (WPS): This document outlines the specific welding processes, techniques, and parameters that a welder must follow during a project. It serves as a guide to ensure consistency and quality in welding.

- Certificate of Compliance: This certificate verifies that the welding work meets all applicable codes and standards. It is often required for project documentation and helps assure clients of the quality of work performed.

- Welder Qualification Test (WQT) Report: This report details the results of the tests that a welder has undergone to demonstrate their skills. It includes information about the tests, results, and any certifications earned.

- Non-Destructive Testing (NDT) Report: This document records the results of tests performed to ensure the integrity of welds without damaging them. It may include methods like ultrasonic or radiographic testing.

- Material Test Report (MTR): This report provides information about the materials used in the welding process, including their specifications and properties. It ensures that the right materials are used for the job.

- Inspection Reports: These documents outline the findings from inspections conducted during or after the welding process. They help identify any issues that may need to be addressed.

- Welding Log: A record of all welding activities performed, including dates, locations, and types of welds. This log helps track the welder's progress and performance over time.

- Quitclaim Deed: This form facilitates the transfer of property ownership rights without any guarantees regarding the title, making it essential for parties to conduct proper due diligence. More information can be found at https://nyforms.com/quitclaim-deed-template/.

- Safety Data Sheets (SDS): These sheets provide detailed information about the materials and chemicals used in the welding process, including safety precautions and handling instructions.

- Training Records: Documentation of any training or certifications the welder has completed. This helps verify that the welder is qualified and knowledgeable about current industry practices.

Using these documents alongside the Welder Performance Qualification Record ensures a thorough understanding of the welding process and helps maintain high standards of quality and safety. Proper documentation is key to successful welding projects.

Check out Popular Documents

Cash Receipt Format - Many businesses develop their Cash Receipt forms to fit their branding needs.

For those looking to create a Bill of Sale form in Illinois, resources such as PDF Documents Hub can provide guidance and templates to help ensure that all necessary information is included for a valid transaction.

How to Fill Out a Payroll Check - Essential for ensuring timely payment to employees.

Key Details about Welder Performance Qualification Record

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record form documents a welder's qualifications and capabilities. It serves as proof that a welder has successfully completed specific tests and meets the standards set by relevant codes or specifications. This form is essential for employers and regulatory bodies to ensure that welders are skilled and capable of performing their tasks safely and effectively.

Who needs to fill out the Welder Performance Qualification Record form?

The form must be completed by certified welding inspectors or authorized personnel who oversee the qualification testing. Additionally, the welder undergoing qualification must provide personal details and sign the form to affirm the accuracy of the information. This collaboration ensures that all data reflects the welder's true capabilities.

What information is required on the form?

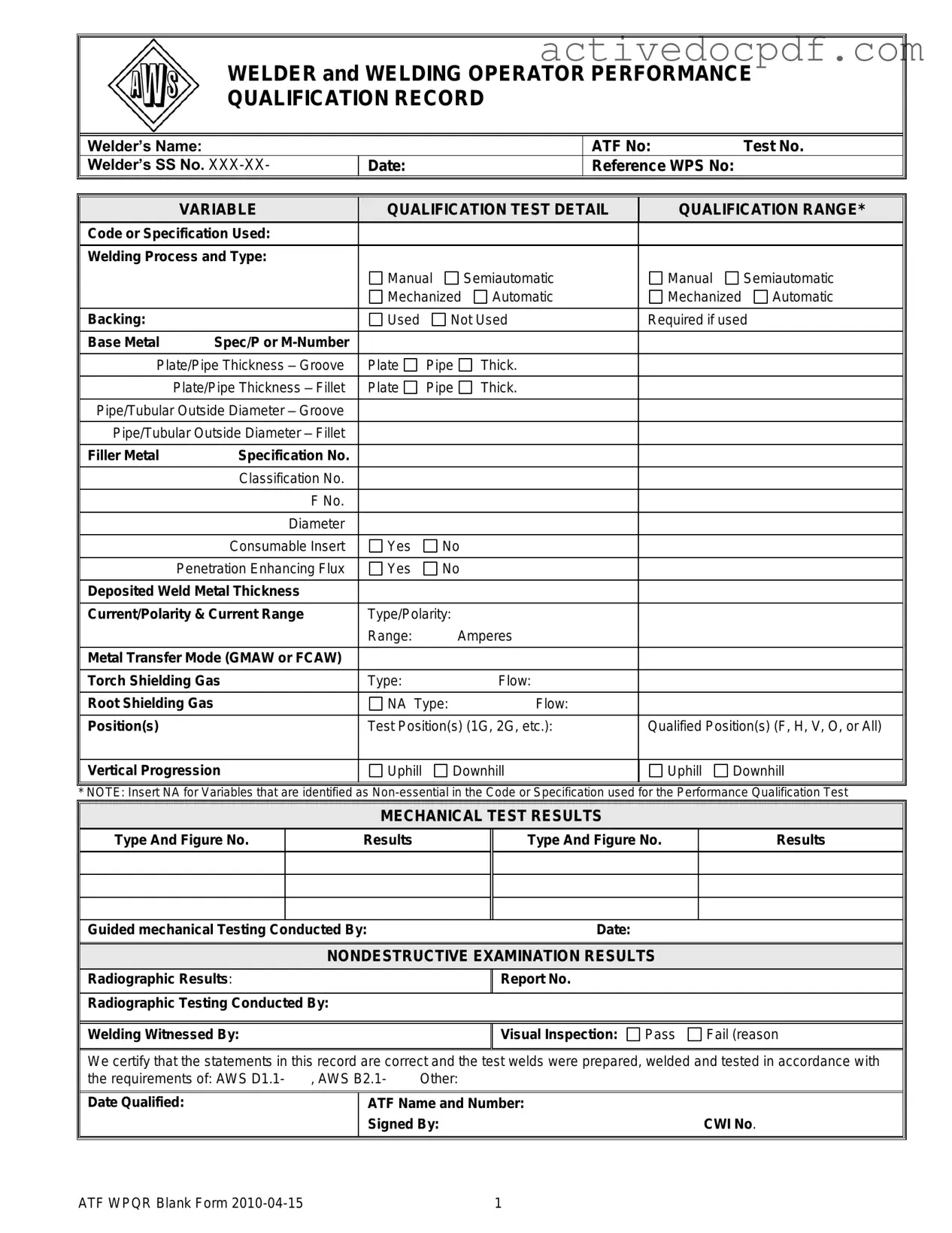

The form requires various details, including:

- Welder's name and identification numbers

- Test number and date

- Reference WPS (Welding Procedure Specification) number

- Welding processes and types used

- Base metal specifications and thickness

- Filler metal specifications and classifications

- Test positions and mechanical test results

- Non-destructive examination results

This comprehensive information helps assess the welder's qualifications accurately.

What types of welding processes are covered?

The form covers various welding processes, including manual, semiautomatic, mechanized, and automatic welding. Each process has specific requirements and qualifications, allowing for a wide range of welding applications. The welder must indicate the processes they are qualified to perform on the form.

What is the significance of the mechanical test results?

Mechanical test results provide evidence of the quality and strength of the welds produced by the welder. These tests help determine whether the welder meets the necessary standards for performance. Results from guided mechanical testing are recorded on the form, ensuring transparency and accountability in the qualification process.

What does the non-destructive examination involve?

The non-destructive examination (NDE) assesses the integrity of the welds without causing damage. This examination may include radiographic testing and visual inspections. The results are documented on the form, providing additional verification of the weld quality. A pass or fail designation indicates whether the welds meet the specified criteria.

How long is the Welder Performance Qualification Record valid?

The validity of the qualification record may vary based on industry standards, employer policies, or specific codes. Generally, qualifications remain valid as long as the welder continues to practice their skills and does not have significant gaps in their welding experience. It is advisable to check with relevant authorities or employers for specific validity periods.

Who signs the Welder Performance Qualification Record form?

The form must be signed by the certified welding inspector (CWI) who conducted the testing, as well as the welder. The signatures affirm that the information provided is accurate and that the tests were conducted in compliance with the applicable standards. This step is crucial for the authenticity and acceptance of the qualification record.

Similar forms

-

Welding Procedure Specification (WPS): The WPS outlines the specific welding parameters and procedures that a welder must follow during the welding process. Like the Welder Performance Qualification Record, it serves to ensure that the welding is performed consistently and meets the required standards. Both documents are essential for maintaining quality and safety in welding operations.

-

Procedure Qualification Record (PQR): The PQR documents the results of tests performed to qualify a specific welding procedure. It includes details about the welding process, materials, and test results, similar to how the Welder Performance Qualification Record provides information about the welder's qualifications and test results. Both documents are crucial for verifying compliance with industry standards.

- Motorcycle Bill of Sale Form: For clear documentation in motorcycle transactions, consider the necessary Motorcycle Bill of Sale form requirements to ensure a legal transfer of ownership.

-

Certificate of Compliance: This certificate confirms that the welding work complies with specified codes and standards. Like the Welder Performance Qualification Record, it serves as proof of qualification and adherence to safety and quality requirements. Both documents play a vital role in ensuring that welding practices meet regulatory expectations.

-

Welder Certification: This document indicates that a welder has successfully completed a qualification test and is certified to perform welding according to specific standards. Similar to the Welder Performance Qualification Record, it provides evidence of the welder's skills and capabilities, ensuring that only qualified individuals perform critical welding tasks.

Guide to Filling Out Welder Performance Qualification Record

Filling out the Welder Performance Qualification Record form is a straightforward process, but attention to detail is crucial. This form captures essential information about a welder's qualifications and the specifics of the welding tests conducted. Follow these steps to ensure that you complete the form accurately.

- Start by entering the Welder’s Name at the top of the form.

- Fill in the ATF No and Test No in the designated fields.

- Provide the Welder’s SS No (Social Security Number) and the Date of the test.

- Record the Reference WPS No (Welding Procedure Specification Number).

- Specify the Code or Specification Used for the qualification.

- Select the Welding Process and Type (Manual, Semiautomatic, Mechanized, or Automatic) and indicate if Backing was used.

- Fill in the Base Metal Spec/P or M-Number and the thickness of the plate or pipe for both Groove and Fillet welds.

- Provide the Outside Diameter for both Groove and Fillet welds.

- Enter the Filler Metal Specification No, Classification No, and F No along with the Diameter.

- Indicate if a Consumable Insert was used and whether Penetration Enhancing Flux was applied.

- Record the Deposited Weld Metal Thickness and specify the Current/Polarity & Current Range.

- Fill in the Metal Transfer Mode (GMAW or FCAW) and the Torch Shielding Gas Type with its Flow rate.

- Specify the Root Shielding Gas if applicable, including its Type and Flow.

- List the Test Position(s) (e.g., 1G, 2G) and the Qualified Position(s) (F, H, V, O, or All).

- Indicate the Vertical Progression (Uphill or Downhill).

- Complete the MECHANICAL TEST RESULTS section by entering the type and results of the tests conducted.

- Provide the name of the Guided Mechanical Testing Conducted By and the Date.

- Fill in the NONDESTRUCTIVE EXAMINATION RESULTS with the Radiographic Results and Report No.

- Specify who conducted the Radiographic Testing and who witnessed the welding.

- Complete the Visual Inspection section, indicating if it passed or failed, and provide the reason if it failed.

- Certify the information by signing the form and providing the Date Qualified, ATF Name and Number, and CWI No.